Share This

Projects

Triple Clamps

Triple clamps for Frank Giannini (http://www.gianniniracing.com/). I like the contrast of the mill finish and the machined...

read moreCNC Touch Probe

I bought this probe head and fitted it to the machine a couple months ago. I finally had a chance to get it dialed in and start using it. The probe tip is set on to the spindle centerline. The small divisions on the indicator are 0.0005″. This is acceptable for now. I may try to get it closer later. The probe finding the center of a bore. I ran this probing sequence twice and the Y coordinate repeated more closely than the X coordinate. I’ll investigate that later. The photo shows the probe being used to locate a triple clamp for...

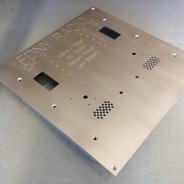

read moreFDNY Radio Console

Machined aluminum plate for FDNY Radio Console. A variety of switches, knobs, speakrs, phone handsets, and LEDs get mounted to this panel.

read moreBrass Hardware

Some custom machined brass hardware to attach the legs of a table. The rounded face matches the rounded wood surface of the...

read moreHat Block

3D Milling of a form for felt hat making. These nine hats are the forms for one style in nine...

read moreSimple 3D milling

Rush foundry pattern for a repeat client. .025″ final step down with a square end cutter. We didn’t have any appropriate ball end cutters on hand and the client was in a rush so this will be hand finished by the...

read moreCNC Probe

I wanted to add the capability to probe to our CNC milling machine. I looked at the 3D taster style indicator which I have used on a manual machine but for less money I thought I could set up an electronic probe that would find edges and surfaces but could also easily locate hole centers and do point cloud probing of 3D surfaces. I purchased some two used Renishaw probe heads plus an optical transmitter. Renishaw invented this style of probe. Since this machine has limited Z travel I ditched the optical transmitter and mounting plate and set...

read moreRS125 rear sets

We just finished up these 3 pairs of rear sets for a race team. I made one test piece that turned out to be extra. I put it back on the mill and pocketed it out to see what kind of weight I could take off. 121 vs 196 grams. Solidworks is fairly accurate predicting the weight of these parts (118.1 and 193.9 grams). On the actual parts the holes are only predrilled which accounts for the low Solidworks...

read more