Share This

Test Blog

Automatic Keurig Coffee Maker

We were asked to mount the provided DC gear motor onto the shaft that would normally carry the handle that opens the coffee maker. After measuring we machined a steel part to adapt the shaft of the gear motor to the fiber reinforced plastic knob on the coffee maker shaft. A simple aluminum bracket to hold the motor body finished the project. You can follow the rest of this project on Anthony’s Blog: Gotham Automatic Brewer 9000.

Planters revisited: Patina

We made these planters almost a year ago. The copper material was left untreated and this nice patina is the result. There are a variety of other options including protecting the bright copper finish and chemically altering and / or accelerating the aging process.

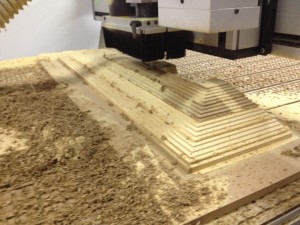

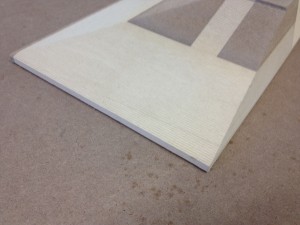

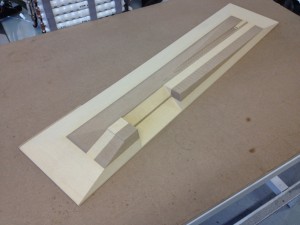

Simple 3D milling

Rush foundry pattern for a repeat client. .025″ final step down with a square end cutter. We didn’t have any appropriate ball end cutters on hand and the client was in a rush so this will be hand finished by the client.

CNC Probe

I wanted to add the capability to probe to our CNC milling machine. I looked at the 3D taster style indicator which I have used on a manual machine but for less money I thought I could set up an electronic probe that would find edges and surfaces but could also easily locate hole centers and do point cloud probing of 3D surfaces.

I purchased some two used Renishaw probe heads plus an optical transmitter. Renishaw invented this style of probe. Since this machine has limited Z travel I ditched the optical transmitter and mounting plate and set out to fabricate my own mounting plate that would also hold a connector to wire to the machine controller.

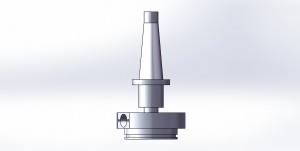

Solidworks model of the tool holder and mounting plate:

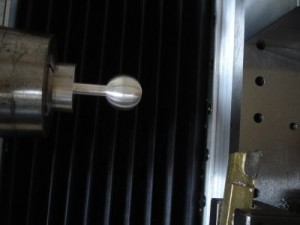

Lathe work:

Machining for connector to machine controller:

Finished adapter plate:

Finished assembly. Tool holder, adapter plate, and Renishaw probe head.

RS125 rear sets

We just finished up these 3 pairs of rear sets for a race team. I made one test piece that turned out to be extra. I put it back on the mill and pocketed it out to see what kind of weight I could take off. 121 vs 196 grams. Solidworks is fairly accurate predicting the weight of these parts (118.1 and 193.9 grams). On the actual parts the holes are only predrilled which accounts for the low Solidworks estimate.

Machining

A few pictures of some machine work. The first two are parts for a shop built CNC lathe I completed a couple years ago. The last is a ball turned using the CNC lathe.

Frisco tank

This is a couple years old but I found these pictures on my computer and thought people might be interested.

Desmo Tank

Bespoke fuel tank for 250 Desmo to replace the high capacity racing tank that was on the bike. The shape of this tank gives good capacity, comfortable riding position, and clearance for the clip-ons. It also emphasizes the recessed Esso fuel filler cap. Tank was shaped in several pieces and TIG welded together before final planishing (smoothing).

19 gauge steel with machined steel fittings and Bakelite fuel cap.