Share This

Test Blog

US Capitol Name Plate Holders

I was excited to get this job from the US government. It is an honor to have my work in the US Capitol building! Brass name plate holders that allow the name plates to be changed easily. Brass is great to work with and doing a relatively large number gave me a chance to experiment with a vacuum fixture which went well.

Vacuum Fixturing

This is my first foray into vacuum fixuring. Fixture is aluminum with 1/8″ rubber o-ring stock. Overall it was successful but I have some things I will do differently next time. The fixture is designed so I could side mill both ends and spot drill with a carbide drill/mill. The cutting action on the left end was pulling the stock away from the fence and I needed to reduce the feed dramatically to keep the stock from sliding. An extra stop or full slot for the material would fix this. I originally had a .1″ deep slot for the o-ring which was too shallow and held the part above the fixture. I increased the depth of the slot which worked but next time I would increase the width of the slot to allow the o-ring to flatten out.

Finished part. Through holes drilled on manual vertical mill.

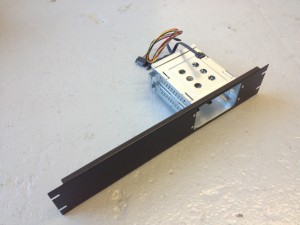

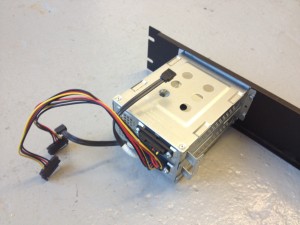

Rack mount hard drives in use

The client for this rack mounted hard drive bay (http://www.gothammachine.com/2013/10/21/19-rack-mount-3-5-hard-drive/) emailed to say he was pleased with being able to being able to swap drives without taking apart his whole rack. Nice setup and I like hearing from happy clients.

Ducati Swingarm on my surface plate

Ducati 1098 Swingarm on my surface plate. Getting some initial measurements of the location of the chain line.

Coffee Table

Tube steel coffee table to receive a wood top. Rubber leveling feet retract into tube end.

I went to a friend’s shop with these fixture tables to set up and tack this table.

19″ Rack Mount 3.5″ Hard Drive Bay

Allows swapping of hard drives in customers rack.

19″ racks are a good, economical way to neatly store a lot of hardware.

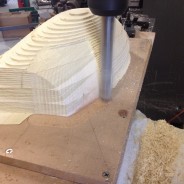

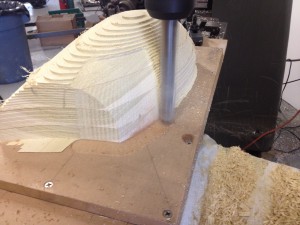

Hood Block

A designer for The North Face saw hat blocks I made a few months ago and asked if one could be done for a hood. The hood block will be machined in two halves, glued together and finished. The piece begins as a stack of wood glued together.

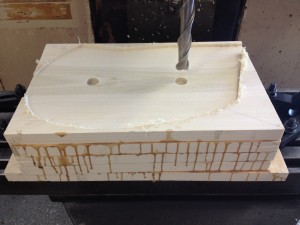

What will be the inside of one half is faced and holes are drilled for registration.

Mirrored on the other half.

The blocks are cut with a bandsaw using the milled area as a guide.

Simple fixture to register the holes in the block to the mill table.

First roughing operation.

Second roughing operation.

First finishing operation.

Second finishing operation.

Two milled halves with registration plugs

Outside of two milled halves.

Gluing and clamping.

Finishing.