Share This

Test Blog

Electric Ducati Parts

Visible progress is a bit slow on this project so here are some images of the parts waiting to go on.

Electric motor mockup

I’m working on putting a big electric motor into a Ducati 1098. Client did not want to send the motor as it weighs 30.5 kgs (67+ lbs!). I machined this dimensionally accurate mockup to aid fitting the rest of the components.

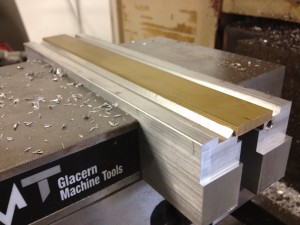

Soft jaws

Last time around I made these parts on a vacuum fixture but due to the small surface area (and maybe the slot for the o-ring being slightly too deep) I had marginal clamping force which led to low feed rates. I have a bunch of these parts to make so I wanted easy secure clamping. The parts are 9.5″ long in my 6″ vice. The threaded hole in the end of the jaw is to attach a locating stop for the 2nd and 3rd drilling operations.

Slots allow changing soft jaws without fully removing jaw screws.

Finished machined jaws. Length machined to allow minimal overhang. Steps to hold work and clearance slot for chamfer cutter.

Part after second operation up against the stop.

Third operation. Part in the lower step up against the stop. You can see the combo drill countersink.

Coil spring diameter

Coil spring diameter is hard to measure with calipers but easy to measure with a surface plate and height gauge.

Rack mount FDNY radio panel

Radio panels that fits in standard 19″ rack. 7U height. Engraved and painted test.

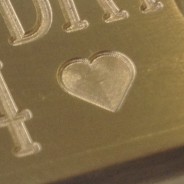

I like the volume knob symbol showing the machining marks.

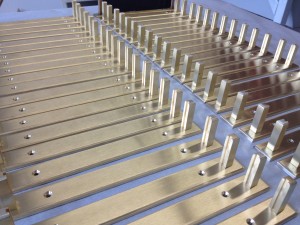

US Capitol Name Plate Holders

Name plate holders for the United States Capitol Building.

360 Brass, fasteners.

Client provided sample in background. Reproduction in foreground. Color difference is due to natural oxidizing of brass that has taken place in the sample.

Several of the holders visible in this image including one on the far left with no name plate inserted.