19 gauge steel with machined steel fittings and Bakelite fuel cap.

Rear Sets and Levers...

posted by Will

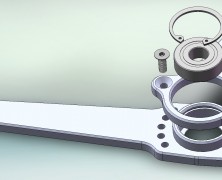

This small project is a good example of how working with a prototype shop can quickly bring a design into reality while accommodating design changes along the way. For those who are not familiar with racing motorcycles, the bracket shown is a “rear set” which moves the foot pegs...

Shift / Brake Levers

posted by Will

A pair of shift / brake levers for a custom Honda 350 race bike. Solidworks model showing the inside of the lever with the bore for the bearing and internal snap ring groove. I wanted to do a test interpolating the bearing bore. The first two attempts were unsuccessful due to the snap ring...

Clark’s first ...

posted by Will

This minibike was gifted to me by my friend Dean when I was in third or forth grade. This machine gave me many pleasurable hours of both riding and wrenching until I got a car and temporarily gave up two wheeled vehicles. This spring while visiting Ted Dillard (http://evmc2.wordpress.com/)...

Crank for Tree Knee

posted by Will

The crank that raises and lowers the knee on our CNC Mill was lost somewhere before the mill came to us. After some measuring I generated a quick Solidworks model and used HSMWORKS to make the tool path. Between the “teeth” you can see some of the adaptive clearing strategy that...

Burro Camper to Mobi...

posted by Will

This was an interesting fiberglass project. We cut up a Burro fiberglass trailer camper to make a mobile bar. The smaller door opens backwards while the long door opens up into a...

Stainless tube table...

posted by Will

We did the tube bending, set-up, and welding on this chair and accompanying table a few months ago for a design student’s senior thesis project. The final results can be viewed on his website:...

Another electric mot...

posted by Will

Some new photos showing the mount test installed on the customer GSXR...

Copper Planters

posted by Will

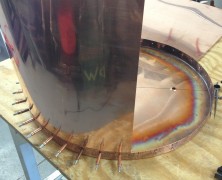

Copper planters with hand bucked 1/4″ round-head copper rivets. The bottoms and rolled lips were both hammer-formed. The form for the bottom was plywood. It took a few rounds of hammering and annealing to achieve the final shape. In the end I resorted to hand tucking the copper and...