Soft jaws

Last time around I made these parts on a vacuum fixture but due to the small surface area (and maybe the slot for the o-ring being slightly too deep) I had marginal clamping force which led to low feed rates. I have a bunch of these parts to make so I wanted easy secure clamping. The parts are 9.5″ long in my 6″ vice. The threaded hole in the end of the jaw is to attach a locating stop for the 2nd and 3rd drilling operations.

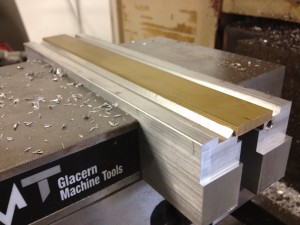

Slots allow changing soft jaws without fully removing jaw screws.

Finished machined jaws. Length machined to allow minimal overhang. Steps to hold work and clearance slot for chamfer cutter.

Part after second operation up against the stop.

Third operation. Part in the lower step up against the stop. You can see the combo drill countersink.