BRIO meets Arduino?

I’m using this post to gather my ideas and maybe gather some like minded helpers with some different skill sets.

Project: Remote control BRIO compatible electric trains and accessories.

I’ve always been intrigued by model railroading and did a bit as a kid. However, traditional model railroads take quite a bit of time to set up and are often left that way for awhile. I’ve recently been playing with Duplo lego blocks with my son. I love how quickly you can put something together and tear it down. My vision for this project is a train set that you can assemble and disassemble quickly but still have the fun of remotely operating a locomotive.

- Background / Inspiration

- Bill of Materials

- RC Electric Locomotive

- RC Switches

- Control Panel

- PCB Milling

- Ideas for the Future

Background / Inspiration

BRIO

Hand Made Wooden Trains

Hoogerland National Railway

Whittle Shortline Railroad

Bill of Materials

- Bill of Materials (Google Doc)

RC electric locomotive

Design requirements

- Minimum: on (forward), off

- Basic: forward, reverse, off

- Ideal: speed control (pwm) forward, reverse, off

- Overkill: lights, sounds etc

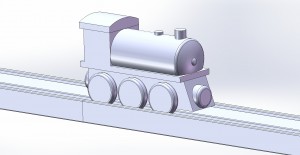

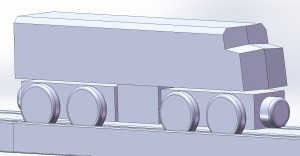

Train Design

- Train type.

- Solid, three wheels (steam).

- Articulated trucks (diesel).

- Solid, three wheels plus coal car (steam).

- Coupling.

- Height from track?

- Ceramic Magnet

- Round Head Nail

- Wheels?

- 3/4″ Maple Dowel

- Wooden Dimes

- Traction, high center, turning radius.

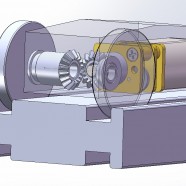

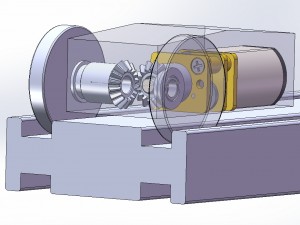

Drivetrain Design

- Electric gear motor. Pololu Micro Gearmotors

- .75″ wheel diameter –> 2.36″/rev. 120rpm(6V) motor –> 4.71″/sec. 170rpm(6V) motor –> 6.68″/sec.

- 40mA no load current, 700mA stall current.

- Micro Gearmotor – 140 RPM @ 6V

- Bevel gears. A 1M 4MYZ05 from SDP/SI Acetal ok? Brass or steel available in slightly larger sizes and 20x the cost.

- Bearings. (3mm x 6mm x 2mm)

Flange orno flange. Bearings will be retained by wheels. - Driven wheels?

- Aluminum?

- How do driven wheels attach to shaft?

- O-rings for traction?

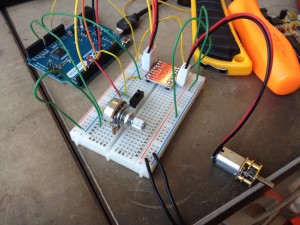

Electronics Design

- XBee.

- Series 1 is fine.

- XBee has two PWM pins (16khz)

- XBee Pinout

Adafruit USB XBee Adapter- Adafruit XBee Adapter Looks more compact than Sparkfun’s version.

Sparkfun XBee Explorer Regulated- I think I can do xbee only in loco, no microcontroller

- Sparkfun Motor Driver Logic 2.7-5.5VDC, Motor 15VDC max, 1.2A. Pins: Standby plus PWM and 2 direction pins per motor.

- Using the Sparkfun Motor Driver 1A Dual TB6612FNG – a Beginner’s Guide

- Flyback diodes needed? Easy and cheap, why not!

- Sparkfun AAA 750mAh.

- 4 AAA holder may barely fit the scale of these trains.

Sorry about the focus. The video shows an Arduino controlling the DC gear motor with speed (potentiometer) and direction (SPDT switch) inputs.

Same wiring as above but changed Arduino code to control direction and speed from one potentiometer.

This is pretty much full featured. Single potentiometer controlling motor speed and direction. The motor isn’t turning very smoothly so that’s the next thing to investigate.

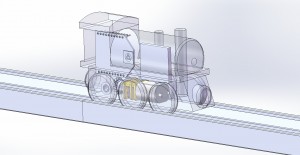

CAD Work

The transparent “house” shape is the size Evan Stephens recommends for his articulated trucks. I’m debating a shorter locomotive with fixed axles vs a longer one with articulated trucks. Maybe a locomotive and a connected coal car to carry some electronics.

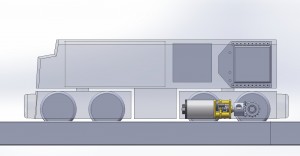

I can fit the Xbee and a motor driver board in this design. Batteries would go in an attached coal car.

Diesel engine with articulated trucks. I could fit Xbee, motor driver, and 4 AAAs in this design.

Packaging is going to be tight. Rectangle at front of loco is 4 AAA battery pack. The square in the middle is the Sparkfun motor driver board. The Xbee board at the rear. I’ll probably swap the battery to the back to keep the weight over the driven wheels.

RC electric switches

Two position “Y” type switch. There are a couple different styles available. I have this on hand for experimentation:

Mechanical Design

- Solenoid?

Electronics Design

- XBee?

- Bluetooth?

- IR?

- Arduino?

- Motor driver?

- Battery?

Control panel

Modular?

Locomotive control.

- Encoder?

- Potentiometer?

Control one or more switches.

- Toggle switches?

Battery?

Plug in?

Do I need Arduino in control panel?

PCB Milling

- Cutter size? Type? I think people are using 30 degree engraving cutters to cut traces.

- Endmill to profile board and cut slots / holes?

- Drill size?

- G-code generation?

- Work holding. Double sided increases complexity slightly.

Ideas for the future:

Multiple locomotives

Bridges

Cranes

Turntable