Hood Block

A designer for The North Face saw hat blocks I made a few months ago and asked if one could be done for a hood. The hood block will be machined in two halves, glued together and finished. The piece begins as a stack of wood glued together.

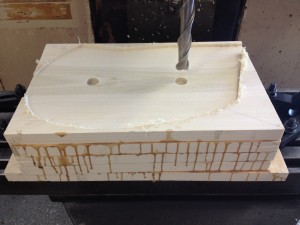

What will be the inside of one half is faced and holes are drilled for registration.

Mirrored on the other half.

The blocks are cut with a bandsaw using the milled area as a guide.

Simple fixture to register the holes in the block to the mill table.

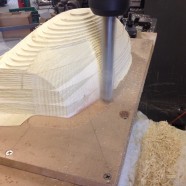

First roughing operation.

Second roughing operation.

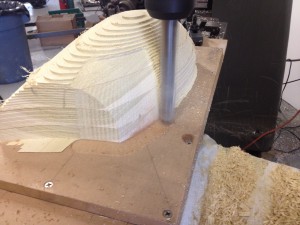

First finishing operation.

Second finishing operation.

Two milled halves with registration plugs

Outside of two milled halves.

Gluing and clamping.

Finishing.